Suspension system

It is customary to distinguish conventionally three main elements in the suspension system: elastic, damping and guiding. The elastic element (springs) is responsible for ensuring smooth running over uneven surfaces, reducing the effect of vertical vibrations on the sprung mass. The aim of the damping element (shock absorbers) is to extinguish the car’s vibrations by converting kinetic energy into heat through friction. The guide element provides correct wheel alignment angles, their correct position relative to the car under the influence of all arising loads. Suspension elements can be implemented constructively in a variety of ways, but their general objective is always the same - smoothing and damping of vibrations and noise caused by driving on uneven roads.

There is a large amount of car suspensions’ types that differ in various design solutions today. The most common suspension system in passenger cars is the McPherson type. In contradistinction to the front suspension system, the rear wheel suspension of passenger cars is often of the dependent or semi-independent type. There are many other types of suspensions from rare to exotic, for example, pneumatic, hydropneumatic, electromagnetic. It is worth highlighting the adaptive suspension system, which adjusts its characteristics to road bumps.

Suspension components need to be replaced over time. In this case, the safety of all passengers directly depends on the quality of the spare parts that are used.

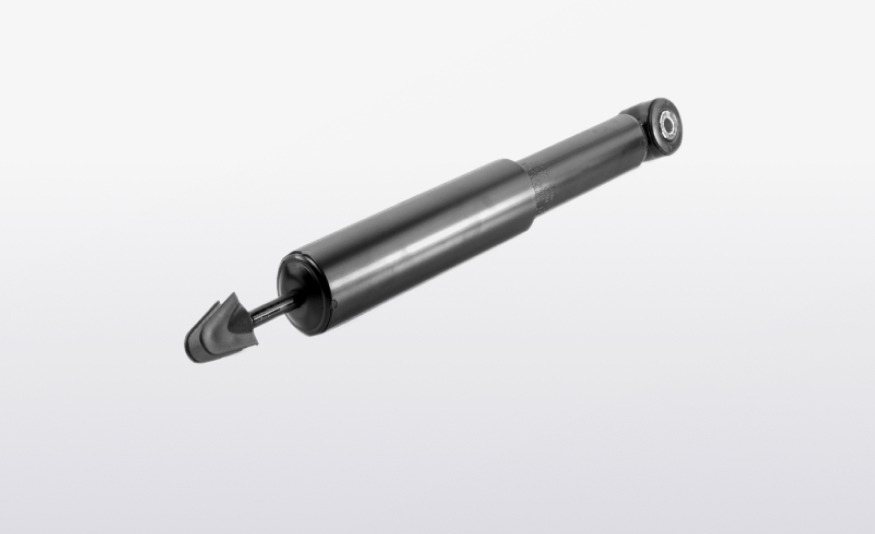

Shock absorbers

A car’s shock absorber is designed to damp vibrations and thereby stabilize the vehicle during driving over road bumps. Moreover, shock absorbers minimize the roll of the car while cornering, accelerating and braking.

It is dangerous to exploit a car with faulty shock absorbers. Defective shock absorbers should also be replaced as soon as possible to avoid damage of other suspension parts.

TMI TATSUMI shock absorbers use premium brands of oils and N.O.K. seals, originally from Japan, for efficient and smooth operation. Polished and heat-treated piston rods with a special anti-corrosion coating guarantee long service life of the shock absorbers with maintaining of all the original characteristics and high efficiency even under the most severe operating conditions.

Coil Springs

Elastic suspension elements, which are coil springs in most modern passenger cars, are used to damp the mechanical energy of the car’s vibrations. The stiffness and geometry of the elastic elements determine a lot of characteristics of the suspension system, as well as the carrying capacity of the vehicle.

Defective and worn springs must be replaced as soon as possible, otherwise there is a high risk of breakage of other suspension elements. TMI TATSUMI coil springs are made of special spring steel. They are also heat-treated during production process in order to increase their service life. Moreover, there is a special coating for corrosion protection.

Strut mount

An important component of the car's damping system is the strut mount. The main aim of the strut mount is the fastening of the shock absorber and the transferring the load to the car body. The serviceability of this element is critical for traffic safety.

TMI TATSUMI strut mounts are characterized by an optimal balance between elasticity of their damping elements and overall construction’s strength. Reliable operation of the strut mounts at various temperatures is achieved not only due to their design, but also due to special composition of rubber elements with the addition of synthetic rubber.

Protection kit

The boot is responsible for reliability and durability of shock absorber’s work by preventing abrasive and chemically active materials from the roadway from getting on the rod. A high-quality boot must be oil and petrol resistant, its mechanical strength should be sufficient for maintaining its integrity under cyclic mechanical stress at different temperatures, sunlight, abrasive and chemical exposure.

The shock absorber bump must withstand a significant shock load and it shouldn’t lose its properties during a long period of time.

TMI TATSUMI anthers and bumps have an optimal balance between strength and elasticity, and the synthetic rubber used in their production guarantees a long service life at various temperatures. TMI TATSUMI spare auto parts fully correspond to the quality of the original products used on the conveyor assembly lines of automobiles.

Engine/transmission mount

The engine and transmission are connected with the car’s body through special mounts that reduce vibration loads. As these mounts run out, more vibration and noise are transmitted to the car’s body. In a case of a serious breakdown, these suspension elements can simply be even disrupted.

TMI TATSUMI engine and transmission mounts guarantee reliable fixation and amortization at the points of attachment of these elements to the car’s body or to the suspension units due to the use of durable synthetic rubber.

High chemical resistance and preservation of the specified properties at a variety of temperatures are the key points to successful work of these auto parts during the entire period of their exploitation.

Tie rods

The steering system uses tie rods to change the wheels’ angles. The adjustment of the pairs "tie rod – tie rod end" allows to set the correct wheels’ convergence angle.

Excessive deterioration and breaking of tie rods can result in a serious accident.

The special design of TMI TATSUMI tie rods is characterized by reduced internal friction. In addition, it is necessary to mention the high-quality anti-corrosion coating of all metal surfaces of the rods, which provides them a long service life.

Bushing

Rubber-metal products such as stabilizer bushings are intended for attaching the stabilizer to the car body and reducing noise and vibration. The condition of bushings affects not only on noise level in the automobile, but also the efficiency of the stabilizer’s work itself, which means that when they are run out, the overall safety of movement decreases.

TMI TATSUMI stabilizer bushings are manufactured with an optimal balance between elasticity and mechanical strength. The addition of synthetic rubber has allowed the engineers to achieve stable performance over a wide temperature range and has ensured the durability of these auto parts.