Transmission system

Transmission systems differ in the type of drive. The driving wheels in the car can be rear, front or all wheels (the so-called four-wheel drive). Depending on the type of drive, the construction of the vehicle’s transmission can vary significantly.

In the construction of a car's transmission, the engine and the gearbox are traditionally separated by a clutch designed for their short-term separation and smooth connection. After the gearbox mechanism, the transmissions of front-wheel drive and rear-wheel drive cars are significantly different.

In a front-wheel drive vehicle the differential and the main gear are located directly in the gearbox, from which, using the axle shafts and CV joints (constant velocity joints), the torque is transmitted to the front wheels. In a rear-wheel drive car the torque from the gearbox is transmitted to the main gear and differential (located on the rear axle) using the cardan shaft, and then, using the axle shafts, to the driving rear wheels.

Wheel hubs and wheel bearings

Wheel hubs are the component, which connects the vehicle's suspension with a bearing unit that allows the wheels to rotate freely. The hub units have a direct impact on the car's handling. Their failure often leads to an unpredictable change in the direction of the vehicle and to the occurrence of an accident.

TMI TATSUMI wheel hubs and wheel bearings are manufactured from high quality steel and their heat-treated ball tracks are hardened to ensure the highest possible strength. Careful polishing of the ball bearing tracks and the use of balls that meet JIS (Japanese Industrial Standards) extend the service life of the hubs.

In order to protect the auto parts from environmental influence and other negative factors, TMI TATSUMI bearing units use a special highly reliable oil seal for dust protection. A high-effective long-life grease is also used to minimize friction and deterioration.

CV-joints

To transmit torque directly to the drive wheels, constant velocity joints (CV joints) are used. Breakage of CV joints leads to the impossibility of operating the vehicle. Therefore, in case of appearance of suspicious noise during movement (crunching), it is necessary to check urgently the condition of these joints and replace them in time.

TMI TATSUMI CV-joints are manufactured of high-quality steel, their working surfaces are hardened by high frequency currents in order to ensure the required hardness and maximum service life. The high-quality grease minimizes friction and contributes to long-term product performance.

Boot kits

Protection of CV-joints from the ingress of abrasive particles, liquids, etc. is performed by special boot kits. CV joint quickly becomes unusable and requires replacement in case of their damage or a leak.

TMI TATSUMI boot kits are made of synthetic rubber, which retains its stable characteristics at temperature extremes and impact of abrasives, chemically active substances and mechanical stress. Advanced stainless steel clamps guarantee an easy assembly and reliable fixation for the entire period of exploitation.

Drive shafts

Drive shafts of front-wheel drive vehicles have heavy loads and they work in very hard conditions, as they are in direct contact with road mud, particles of bitumen, gasoline, oil at a variety of temperatures. That is why quite strict requirements are imposed on the quality of manufacturing of drive shafts.

If drive shafts fail, the vehicle will not be able to continue driving.

TMI TATSUMI drive shafts are manufactured from high quality steel using heat-treated ball tracks for max. strength. The use of high-quality grease and reliable boots made of synthetic rubber with stainless steel clamps ensures long and reliable operation of these auto parts.

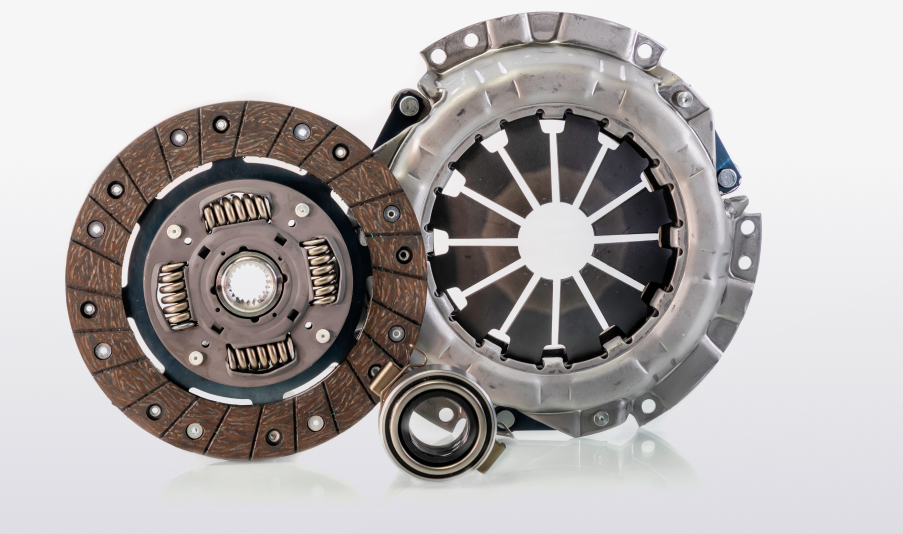

Clutch kit

A car’s clutch is a critical component unit that is subjected to significant mechanical and thermal stress. Its task is to disconnect temporarily an engine and a gearbox. Failure of the clutch will lead to great difficulties in the exploitation of the car (for example, slipping of the clutch) or to a complete impossibility to operate it (refusal to engage or disengage the clutch).

TMI TATSUMI clutch kits are made of high-quality steels and a special friction material is used for reliable transmission of torque. Hardness treatment of diaphragm and tangential springs for heavy duty operations provides a hardened surface layer that significantly increases the service life of the auto part.