Automative electrical equipment

More and more electronic monitoring and control systems, various information systems for a driver and passengers have appeared in the car during recent years. Many systems in modern cars are microprocessor-controlled.

On the one hand, the automation of many processes in the car has increased comfort and safety, but, on the other hand, it is necessary to note a number of negative points: the growth of requirements for the energy intensity of the car’s power grid, a significant increase in a number of breakdowns, as a concomitant factor in the complexity of the construction (up to a third of failures in modern the car falls on electrical components).

Starter

To start an internal combustion engine, it must be rotated to the required speed - this is what the car’s starter is responsible for. A starter is a direct current electric motor with a temporary coupling device of its shaft with the flywheel of an automobile engine.

It is impossible to start the engine normally with a faulty starter.

Starters represent one of the product groups of electrical equipment produced under our brand.

Alternator

An automobile’s alternator converts the mechanical energy of an engine into electrical energy. A alternator supplies all onboard electricity systems and charges the battery when the vehicle's power plant is running.

Alternator’s breakdowns are divided into two main types: mechanical and electrical. In the case of an electrical failure of the alternator, a gradual discharge of the battery occurs or its recharge with a quick failure. Mechanical damage to the alternator is often accompanied by a jamming of the shaft and a failure of the drive belt (with a characteristic whistle). Exploitation of a car with a faulty alternator leads to an increase in costly breakdowns quickly.

Alternators of various modifications are presented in our range.

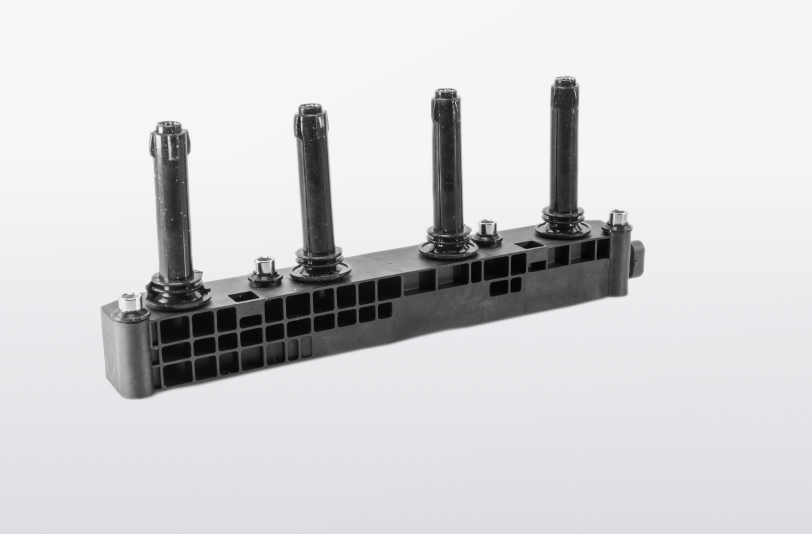

Ignition coil

To form a spark on the spark plugs and ignite the air-fuel mixture in the engine cylinders, high voltage pulses must be generated. This task is done by one or more ignition coils in a car.

In case of its failure, an ignition coil does not generate a sufficient high voltage pulse and a spark discharge does not form on the spark plug. As a result, the fuel mixture is not ignited by this plug. If a defective ignition coil is designed to pulse all spark plugs, the engine will not run. If such a coil is installed on only one cylinder, the engine will lose power and its operation will become unstable.

The modern construction of TMI TATSUMI automotive ignition coils allows to form a strong magnetic field and, thus, optimal output voltage values. The high chemical, thermal and mechanical strength of the coil’s components ensures its efficient operation and durability. The vacuum forming process eliminates voids in the coil’s body.

TMI TATSUMI ignition coils 100% meet OE specifications for proper fit.

High voltage ignition cables

The task of high voltage ignition cables is to transfer an electrical impulse from an ignition coil to spark plugs. Failure of such ignition cables leads to the impossibility of engine’s starting, instability in its operation and a decrease in its power.

TMI TATSUMI high voltage ignition cables are made of high-quality materials and have the following distinctive features: silicone coating provides high chemical and thermal resistance, contacts are highly resistant to oxidation, caps do not lose their shape and insulating properties over the time.

Inductive resistor provides reliable protection against electromagnetic interference. Accurate adherence to OE specifications gives confidence that the products meet their stated dimensions and performance.

Fuel pump

It is customary to refer all the systems and devices that consume electric current, electrical wiring and also current sources - a generator and an accumulator to the electrical equipment of a vehicle. A feature of the car's electrical system is the fact that all devices are connected to the system with only one wire (positive pole) and the negative pole is taken directly from the metal body of the vehicle.

More and more electronic monitoring and control systems, various information systems for a driver and passengers have appeared in the car during recent years. Many systems in modern cars are microprocessor-controlled.

On the one hand, the automation of many processes in the car has increased comfort and safety, but, on the other hand, it is necessary to note a number of negative points: the growth of requirements for the energy intensity of the car’s power grid, a significant increase in a number of breakdowns, as a concomitant factor in the complexity of the construction (up to a third of failures in modern the car falls on electrical components).